Many plastic materials are unable to be recycled and are instead thrown away at the end of their useful lives, often landfilled, incinerated, or littered, polluting land and oceans.

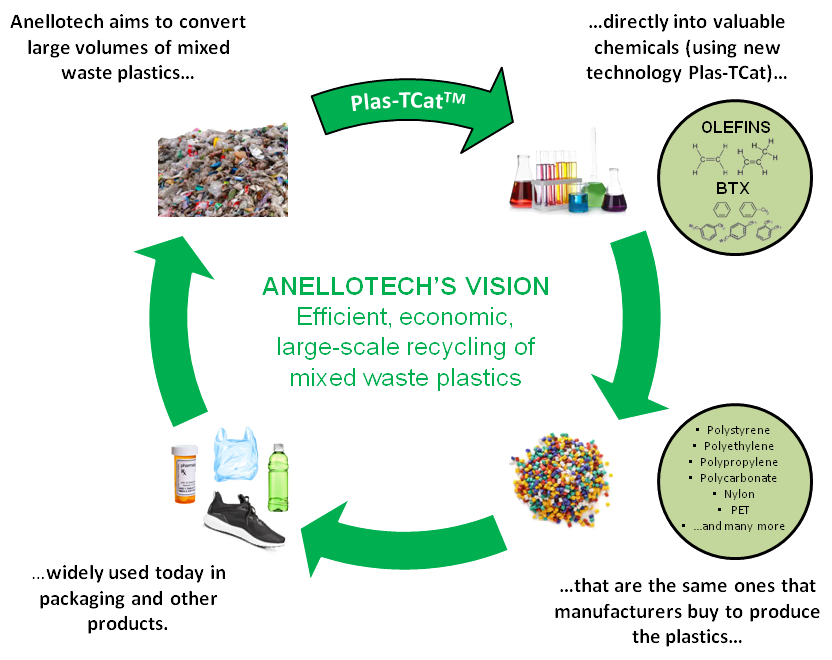

Anellotech has created Plas-TCatTM, a plastic chemical recycling process that converts large volumes of mixed, waste plastics directly into valuable chemicals.

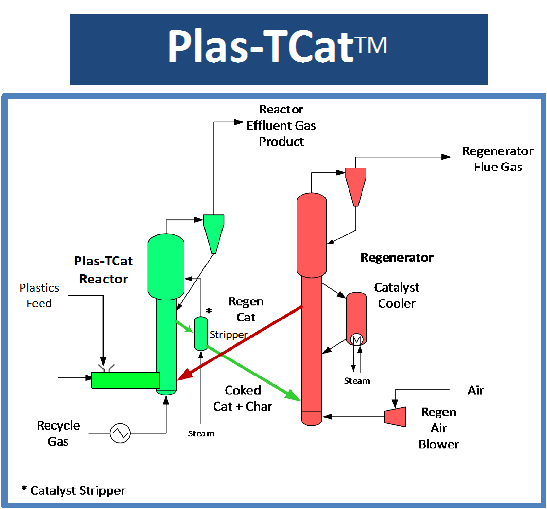

Plas-TCat advantages over non-catalytic processes include ability to feed all plastics (including those containing oxygen (PET, PC) and nitrogen (nylon) without first making an intermediate product.

Anellotech has created Plas-TCatTM, a plastic chemical recycling process that converts large volumes of mixed, waste plastics directly into valuable chemicals.

Plas-TCat advantages over non-catalytic processes include ability to feed all plastics (including those containing oxygen (PET, PC) and nitrogen (nylon) without first making an intermediate product.

Plas-TCat – Plastic Waste Feedstock

Anellotech plans to economically convert plastic waste into globally-marketed commodity chemicals. These aromatics and olefins can be used to make virgin materials including food packaging, plastic components for automotive and other markets.Plas-Tcat can be used to recycle a broad range of mixed plastic waste feedstock, for example:

- Single use plastic

- Flexible packaging

- Flexible films

- Composite plastics

- Plastic containing nitrogen (such as nylon, ABS, polyurethane), oxygen (including PET, polycarbonate) and other heteroatoms

SIX REASONS WHY PLAS-TCAT IS A GAME CHANGER

- Plas-TCat process is a new, direct route to olefins and aromatics from low value plastic waste feedstock

- Competitive economics (double digit IRR%) using market price feedstock; no tipping fees or product price premiums.

- Makes valuable products from range of feedstocks at attractive yields

- Can feed all major plastics due to proprietary catalyst and fluid bed reactor-regenerator system design.

- Product slate can be controlled to maximize aromatics (BTX) or olefins (ethylene, propylene)

- Composites, mixed plastics can be used with minimal presorting of feedstocks (other than PVC reduction)

- Yields can be predicted based on plastic’s chemical composition

- Heteroatoms (O, N, S, Cl) mostly rejected in the form of gases CO, CO2, H2S, N2 to nitriles, Cl removed in pretreatment

- No major chemical upgrading of Plas-TCat products is required

- Aromatics, C2-C4 olefins and paraffins ready for purification and sale or direct feeding into the downstream steam crackers purification trains.

- No upgrading is required in ethylene furnaces -- as for thermal pyrolysis output.

- LCA assessment (preliminary): potential to reduce CO2 emissions up to 50% vs. monomers from fossil resources

- Scalable. Anticipated commercial plants should exceed 200,000 metric tons/year of olefins and/or BTX production from a single reactor system processing majority polyolefin plastic waste.